Pre Engineered Building / PEB Structures

- Home

- Overview of PEB

Overview of PEB

OVERVIEW OF PRE ENGINEERED BUILDING:

-

Pre - Engineered Buildings (PEBs) are buildings that are designed and fabricated in a factory and then shipped to the construction site for assembly. PEBs are typically made of steel, but they can also be made of other materials, such as aluminum or concrete.

PEB is becoming increasingly popular because they offer a number of advantages over traditional construction methods, including:- Faster construction time: PEBs can be constructed much faster than traditional buildings, which is often important for businesses that need to get their new facility up and running quickly.

- Lower cost: PEBs are typically less expensive to construct than traditional buildings. This is because the components are mass-produced in a factory and the assembly process is more efficient.

- Higher quality: PEBs are manufactured in a controlled environment, which helps to ensure that they are of high quality.

- Durability: PEBs are very durable and can withstand a wide range of weather conditions.

- Flexibility: PEBs can be designed to meet the specific needs of any business or industry. They can be used for a variety of applications, including warehouses, factories, office buildings, retail stores, and more.

PEBs are typically assembled using a bolt-together system, which makes the construction process quick and easy. PEBs can also be easily expanded or modified in the future.

Here are some of the common applications of pre-engineered buildings:- Warehouses

- Factories

- Office buildings

- Retail stores

- Aircraft hangars

- Sports arenas

- Concert halls

- Schools

- Hospitals

- Shopping malls

- Airports

- Railway stations

- Power plants

- Oil and gas facilities

PEBs are a versatile and cost-effective construction solution for a wide range of applications. If you are considering building a new facility, PEBs should be at the top of your list of options.

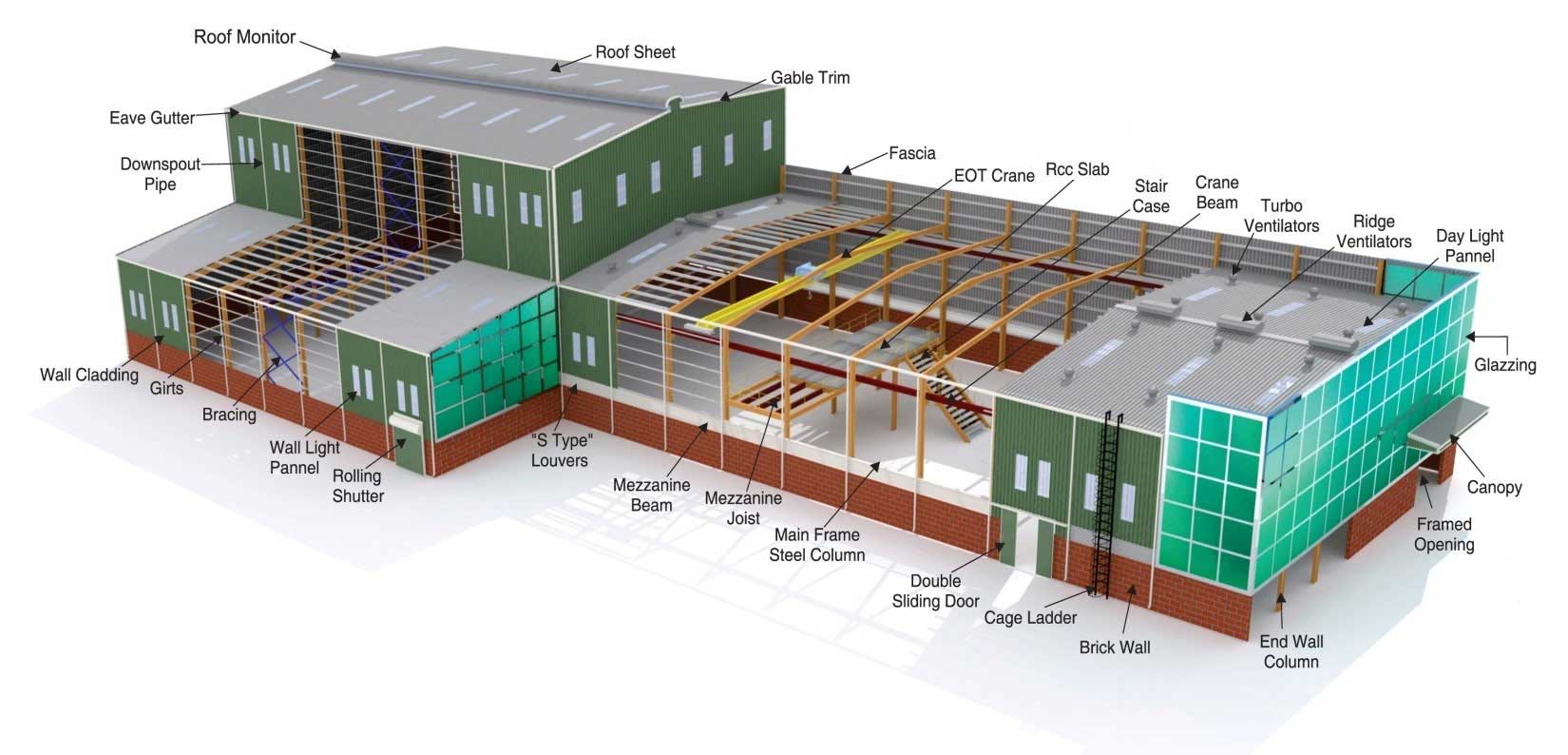

PEB CONSIST OF FOLLOWING THINGS::

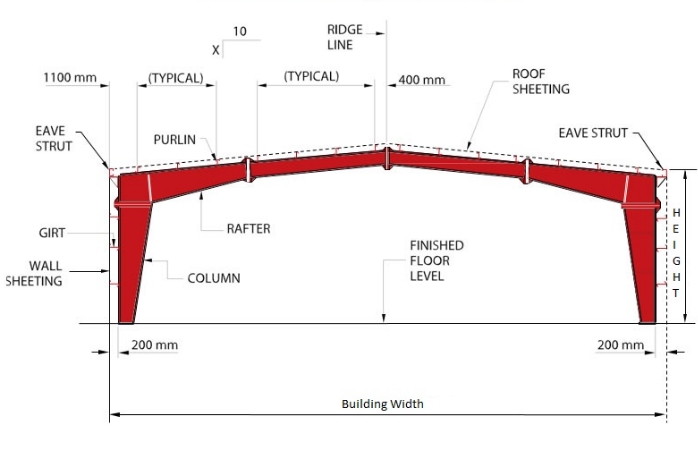

- MAIN FRAME STEEL COLUMN

The main frame steel column used in a PEB is typically a tapered I-section. Tapered columns are used to reduce the amount of steel required in the structure, while still maintaining the necessary strength and stiffness.

The I-section is a very efficient shape for columns, as it provides a high strength-to-weight ratio. The flanges on the I-section provide resistance to bending, while the web provides resistance to shear.

The tapered shape of the column allows the amount of steel to be reduced towards the top of the column, where the loads are lower. This results in a more efficient and economical design.

The steel grade used for PEB columns typically has a high yield strength, such as A36 or A572. This ensures that the columns can withstand the heavy loads that they are subjected to.

The PEB columns are typically fabricated in a factory and then shipped to the construction site, where they are bolted together to form the main frame of the building.

Here are some of the advantages of using tapered I-section steel columns in PEBs:- High strength-to-weight ratio: Tapered columns are very efficient in terms of their strength-to-weight ratio. This means that they can support a lot of weight without being too heavy themselves.

- Reduced material costs: : Tapered columns require less steel than traditional columns, which can save on material costs.

- Faster construction: PEB columns are prefabricated, which means that they can be installed quickly and easily. This can lead to faster construction times and lower labor costs.

PEB columns are used in a wide variety of applications, including warehouses, factories, commercial buildings, and agricultural buildings.

GIRTS

- Girts Detail

Girts also known as Purlins are horizontal structural members that are attached to the main frame columns of a PEB. They are typically made of cold-formed steel and are available in a variety of shapes and sizes. The most common shape for girts is a Z-section, but other shapes such as C-sections and L-sections can also be used.

Girts are used to support the exterior wall panels of a PEB. They are typically spaced 1200 mm to 1500 mm apart, depending on the size and type of wall panels being used. Girts are also used to support any other exterior elements of a PEB, such as windows, doors, and roofing panels.

Girts play an important role in the structural integrity of a PEB. They help to distribute the weight of the exterior wall panels and other elements evenly across the main frame of the building. Girts also help to resist wind and seismic loads.

When choosing girts for a PEB, It is important to consider the following factors:- The type of wall panels being used: : Different types of wall panels have different load-bearing capacities. It is important to choose girts that are strong enough to support the weight of the wall panels being used.

- The wind and seismic loads in the area where the building is being constructed : Buildings in areas with high wind and seismic loads will require stronger girts than buildings in areas with lower wind and seismic loads.

- The budget: Girts are available in a variety of price ranges. It is important to choose girts that fit the budget for the project.

PEB columns are used in a wide variety of applications, including warehouses, factories, commercial buildings, and agricultural buildings.

Girts are an essential component of PEBs. They help to support the exterior wall panels and other elements of the building, and they play an important role in the structural integrity of the building.

BRACING

-

Bracing is a system of structural elements that are designed to resist lateral loads, such as wind and earthquake forces. Bracing helps to keep the building stable and prevents it from collapsing.

There are a variety of different types of bracing systems that can be used in PEBs, but the most common are:- Cross bracing: This type of bracing consists of two diagonal members that are crossed in the middle and connected to the main structural members of the building. Cross bracing is a very effective way to resist lateral loads, but it can also reduce the amount of usable space in the building.

- Chevron bracing : This type of bracing consists of two diagonal members that are connected at the top and bottom to form a V-shape. Chevron bracing is less effective than cross bracing, but it takes up less space.

- K-bracing: This type of bracing consists of two diagonal members that are connected at the top and bottom to form a K-shape. K-bracing is more effective than chevron bracing, but it takes up more space than cross bracing.

The type of bracing system that is used in a PEB will depend on a number of factors, including the size and shape of the building, the expected lateral loads, and the budget.

Bracing is typically installed in the end bays of a PEB and at regular intervals along the length of the building. It is also often installed at the roof level to resist wind forces.

Bracing is an essential part of any PEB, and it is important to ensure that it is properly designed and installed.

Transparent Sheet Panel

-

The most common transparent sheet used in PEB is polycarbonate. Polycarbonate is a thermoplastic polymer that is known for its durability, high light transmission, and resistance to impact, weather, and chemicals. It is also lightweight and relatively easy to install.

Polycarbonate sheets are typically used in PEBs for skylights, sidelights, and curtain walls. They can also be used for interior partitions and other applications where natural light is desired.

Here are some of the benefits of using polycarbonate sheets in PEBs:- High light transmission: Polycarbonate sheets can transmit up to 92% of visible light, allowing for maximum natural daylighting in the building. This can help to reduce energy costs and improve indoor comfort.

- Durability : Polycarbonate sheets are extremely durable and can withstand a wide range of weather conditions, including hail, snow, and high winds. They are also resistant to impact, chemicals, and UV rays.

- Lightweight : Polycarbonate sheets are significantly lighter than traditional glass, making them easier to transport and install. This can help to reduce construction costs and time.

- Easy to install : Polycarbonate sheets are relatively easy to install using a variety of methods, including screws, bolts, and adhesives.

The type of bracing system that is used in a PEB will depend on a number of factors, including the size and shape of the building, the expected lateral loads, and the budget.

Bracing is typically installed in the end bays of a PEB and at regular intervals along the length of the building. It is also often installed at the roof level to resist wind forces.

Bracing is an essential part of any PEB, and it is important to ensure that it is properly designed and installed.

WALL CLADDING & ROOF SHEET

-

Powder coated sheet is a popular choice for wall cladding in PEB Structures. It is a durable and aesthetic option that offers a number of advantages, including:

Here are some of the benefits of using polycarbonate sheets in PEBs:

- Corrosion resistance: Powder coating is a dry finishing process that applies a layer of polymer powder to the metal substrate. The powder is then cured using heat, forming a hard, protective coating that is resistant to corrosion, chemicals and UV rays.

- Durability : Powder coated sheets are highly durable and can withstand harsh weather conditions and heavy use. They are also resistant to scratches and fading.

- Low maintenance : Powder coated sheets are very low maintenance and require only occasional cleaning.

- Aesthetics : Powder coated sheets come in a wide range of colors and finishes, allowing you to create a unique and visually appealing look for your PEB building.

The interior face is pre-painted with 0.5 mm thick factory applied polyester paint. Each panel shall provide one meter coverage and can be shipped in any length up to 12 meter.

In addition to these advantages, powder coated sheets are also relatively lightweight and easy to install, making them a cost-effective option for wall cladding

ROLLING SHUTTER

-

Rolling shutters are a type of door that opens and closes by rolling up and down. They are commonly used in pre-engineered buildings for a variety of reasons, including:

Here are some of the benefits of using polycarbonate sheets in PEBs:

- Security : Rolling shutters provide a high level of security, making them ideal for protecting valuables and inventory. They can be made from a variety of materials, including steel, aluminum, and polycarbonate, each with its own unique advantages.

- Durability : Rolling shutters are designed to withstand heavy use and harsh weather conditions. They are also relatively easy to maintain, making them a cost-effective solution for long-term use.

- Versatility : Rolling shutters can be used in a wide variety of applications, including warehouses, factories, retail stores, and commercial buildings. They can also be customized to fit any size opening.

In pre-engineered buildings, rolling shutters are typically installed on the exterior walls and openings. They can be operated manually or electrically, and can be integrated with security systems for added protection.

DOWNSPOUT PIPE

-

The most common type of downspout pipe used in PEB is galvanized steel. It is strong, durable, and resistant to corrosion, making it ideal for use in harsh environments. Galvanized steel downspouts are also relatively inexpensive and easy to install.

The size of the downspout pipe used in a PEB will depend on the size of the roof and the amount of rainfall that the building is expected to receive. For most PEBs, a 100 mm diameter downspout pipe is sufficient. However, larger downspout pipes may be needed if the roof is very large or if the building is located in an area with heavy rainfall.

Downspout pipes in PEBs are typically installed on the exterior of the building, but they may also be installed inside the building if necessary. The downspouts are connected to the gutters at the roofline and run down the side of the building to the ground. At the ground level, the downspouts are typically connected to a drainage system to direct the rainwater away from the building.

It is important to note that downspout pipes should be inspected and cleaned regularly to ensure that they are free of debris and that they are functioning properly. Clogged downspouts can lead to water damage to the roof and exterior of the building.

EAVE GUTTER

-

Eave gutters are used in PEB to collect rainwater and direct it away from the foundation of the building. This helps to protect the foundation from corrosion and water damage. Eave gutters are typically made of galvanized steel and they are available in a variety of sizes and colors.

When choosing an eave gutter for your pre-engineered building, it is important to consider the following factors :- The size of the roof : The eave gutter should be large enough to collect all of the rainwater from the roof.

- The slope of the roof : The eave gutter should be installed at a slight slope to allow the water to drain properly.

- The climate : If you live in an area with heavy snowfall or rain, you will need to choose an eave gutter that is strong and durable.

Once you have chosen an eave gutter, it is important to install it properly. The eave gutter should be attached to the fascia board of the roof using gutter hangers. The gutter hangers should be spaced no more than 24 inches apart. The eave gutter should also be sloped slightly to allow the water to drain properly.

Once the eave gutter is installed, it is important to clean it regularly to remove any debris that could block the flow of water. Debris can include leaves, twigs, and dirt. If the eave gutter is blocked, the water can overflow and damage the foundation of the building.

ROOF MONITOR

-

A roof monitor is a raised portion of a roof, typically located at the ridge. It is used to provide natural light and ventilation to a building.

Some of the benefits of using roof monitors in PEBs include :- Improved ventilation : Roof monitors help to improve ventilation by allowing hot air and stale air to escape from the building. This can help to create a more comfortable and productive work environment for employees.

- Reduced energy costs : Roof monitors can help to reduce energy costs by reducing the need for mechanical ventilation and air conditioning.

- Increased natural light : Roof monitors can help to increase the amount of natural light in a building. This can help to reduce the need for artificial lighting, which can save money and improve the overall environment of the building.

EOT CRANE

-

EOT cranes or electric overhead traveling cranes, are a type of crane that is commonly used in pre-engineered buildings (PEBs). EOT cranes are suspended from the roof of a building and can travel along two parallel runways. They are capable of lifting and moving heavy loads, making them ideal for a variety of applications, including :

- Manufacturing : : EOT cranes are used in manufacturing plants to move raw materials, work-in-progress, and finished products.

- Warehousing : EOT cranes are used in warehouses to load and unload trucks, store and retrieve inventory, and pick and pack orders.

- Assembly lines : EOT cranes are used on assembly lines to move parts and subassemblies from one station to the next.

- Maintenance and repair : : EOT cranes are used in maintenance and repair shops to lift and move heavy equipment and machinery.

TURBO VENTILATORS

-

Turbo ventilator fans are used in PEB to provide natural ventilation. They are wind-driven, and their rotating blades create a negative pressure inside the building, which draws out hot, stale air and replaces it with fresh, cooler air.

Turbo ventilator fans are particularly well-suited for pre-engineered buildings because they are:- Energy-efficient : : : Turbo ventilator fans do not require any electricity to operate, which can save businesses a significant amount of money on their energy bills.

- Low-maintenance: Turbo ventilator fans are very simple devices, and they require very little maintenance.

- Durable : Turbo ventilator fans are made from durable materials, such as aluminum or stainless steel, which makes them resistant to corrosion and other damage.

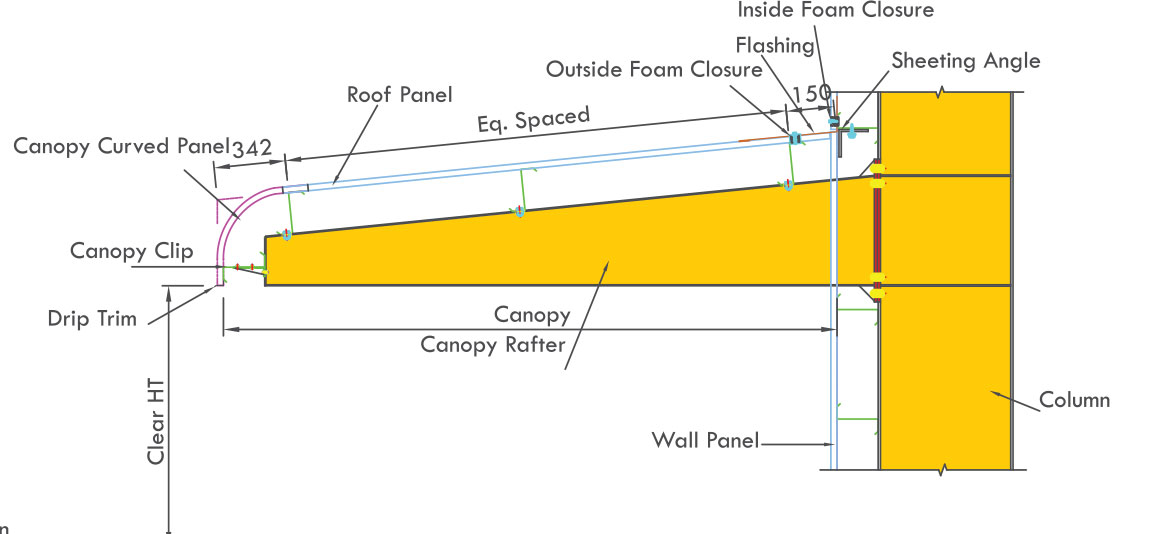

CANOPY

-

A canopy is a roof structure that is typically supported by columns and extends from the main building. Canopies are often used at entrances to buildings to provide shelter from the rain and sun or over walkways and other outdoor areas.

Pre-engineered canopies are typically made of steel and are designed to be easy to assemble and install.

Here are some examples of how pre-engineered canopies can be used in pre-engineered buildings :- Entrance canopy : A pre-engineered canopy can be used to create a welcoming and inviting entrance to a pre-engineered building.

- Walkway canopy : A pre-engineered canopy can be used to create a covered walkway between two pre-engineered buildings, or to protect pedestrians from the elements while walking to and from their vehicles.

- Carport canopy : A pre-engineered canopy can be used to create a covered carport to protect vehicles from the sun and rain.

- Carport canopy : A pre-engineered canopy can be used to create a covered patio area for outdoor dining and relaxation.

LOUVERS

-

Louvers are openings in a wall or roof that are designed to allow air to flow through while blocking out rain, snow, and other elements. They are often used in PEB to provide natural ventilation and reduce heat buildup.

There are two main types of louvers used in PEBs: fixed and adjustable. Fixed louvers are oriented at a fixed angle, while adjustable louvers can be rotated to control the amount of airflow.

Fixed louvers are typically used in light industrial and warehouse buildings. They are easy to install and maintain, and they provide a consistent airflow. Adjustable louvers are more expensive, but they offer more flexibility in controlling airflow. They are often used in commercial and institutional buildings, where it is important to maintain a comfortable indoor environment.

Louvers are typically made of metal or plastic. They can be coated with a variety of finishes to match the exterior of the building.

Here are some of the benefits of using louvers in PEBs :- Natural ventilation : Louvers can help to reduce energy costs by providing natural ventilation. This can be especially beneficial in warm climates, where air conditioning is often used to cool buildings.

- Heat reduction : Louvers can also help to reduce heat buildup inside buildings. This can improve comfort for occupants and reduce the need for mechanical cooling.

- Improved air quality : Louvers can help to improve air quality by circulating fresh air throughout the building. This can help to reduce dust, fumes, and other pollutants.

- Aesthetics : Louvers can also add to the aesthetic appeal of a PEB. They can be designed to match the exterior of the building and create a visually appealing facade.

Basic Building Parameters

Canopy For Better Look of Your Structure